Your Metal Fabrication Partner

From initial concept to final delivery, we provide end-to-end OEM/ODM solutions tailored for global brands.

Advanced Automation

Our Core Services

From raw metal to retail-ready products, we offer a comprehensive suite of services to power your business growth.

Custom OEM / ODM

Transform your original designs into high-quality physical products with flexible manufacturing and strict QC.

Engineering & R&D

Professional CAD & SolidWorks support to optimize structure, cost, and manufacturability.

Surface Treatment

Automated powder coating and anti-rust treatments ensure outdoor durability and premium finishes.

Private Labeling

Retail-ready branding including logo etching, packaging design, and instruction manuals.

Experience

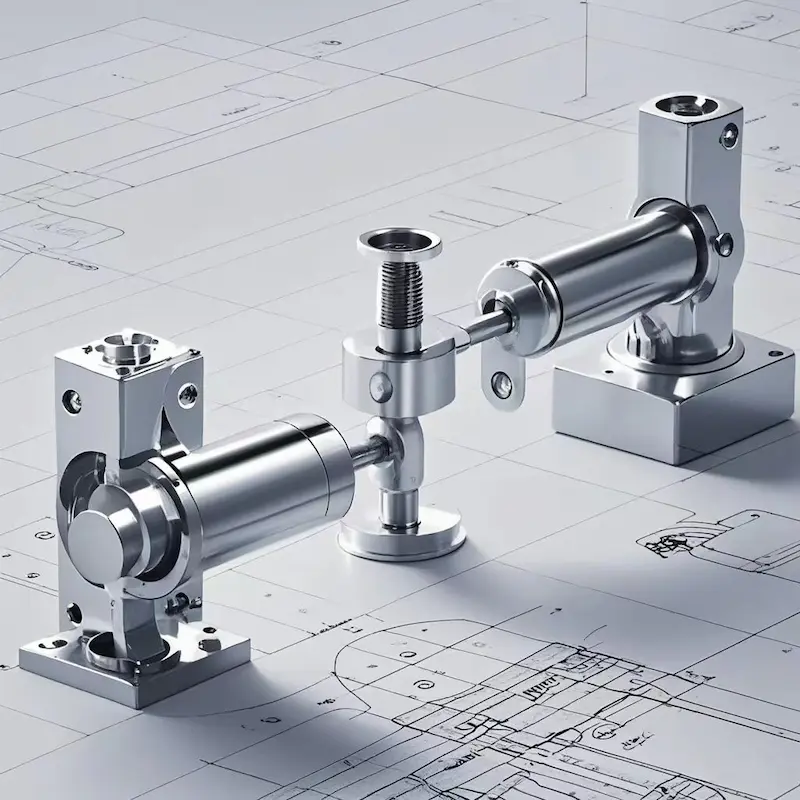

Engineering & R&D Support

Our in-house engineering team uses industry-leading software like AutoCAD and SolidWorks to breathe life into your concepts.

Design Optimization

We refine structures to ensure maximum strength while minimizing unnecessary material weight.

Cost-Efficiency Engineering

DFM optimization reduces production steps and material waste, lowering unit cost.

Stress & Durability Analysis

Virtual stress testing ensures safety before physical prototyping.

Advanced Production Technology

Our 18-year expertise is backed by state-of-the-art machinery, ensuring every cut, weld, and finish meets global industrial standards.

CNC Laser Cutting

High-precision fiber laser cutting for complex steel and aluminum parts with ±0.1mm tolerance.

- Smooth Edges (Burr-Free)

- High Material Utilization

Robotic Welding

Automated welding cells deliver 100% consistent weld seams across large-scale production.

- Superior Structural Strength

- Zero Human Fatigue Error

Automated Coating

Continuous conveyor coating line with multi-stage pre-treatment and uniform outdoor-grade finish.

- Anti-Rust & UV Protection

- Eco-Friendly Process

Private Label & Packaging

Build your brand authority with our comprehensive private labeling services. We ensure your products arrive shelf-ready and fully aligned with your brand identity.

Logo Branding

Laser etching, silk-screen printing, or embossed steel logos.

Custom Packaging

Full-color mailer boxes, reinforced cartons, and PDQ displays.

Manuals & Inserts

Multi-language instruction guides and marketing inserts.

FBA Labeling

Barcode printing, SKU labeling, and Amazon-compliant prep.

Small-batch OEM branding is available for selected models.

Request Branding Guide

Professional Finish

Enhance your retail perceived value.

Turning Challenges into Results

See how our engineering team optimized a client’s design for better performance and lower costs.

High Production Cost & Structural Noise

A US-based hunting brand approached us with a tree stand that was too heavy for mobile hunters and produced metallic noise during movement — a critical issue in the field.

- Material Swap: High-tensile 6061 aluminum reduced weight by 25%.

- Acoustic Engineering: Silent-lock nylon washers eliminated noise.

- Cost Reduction: Folding redesign cut shipping volume by 15%.

“Chuanfoo didn’t just manufacture our design — they made it better. Shipping costs dropped 12%, and noise-related returns are now zero.”

— Lead Product Manager, US Outdoor Gear Brand

-25%

Product Weight

-12%

Shipping Volume

0%

Noise Complaints

100%

On-time Delivery

Have a Complex Project? Let’s Solve It.

Our engineering team is ready to review your blueprints and provide a comprehensive manufacturing assessment—free of charge.